Anodized Aluminium Sheet are well-known for their unique properties and adaptability, which makes them a great choice for many sectors. Anodizing improves the surface of aluminum by adding a layer that is strong and resistant to rust. This treatment makes aluminum look better and makes it last longer by making it more resistant to wear and tear. Because of their better qualities, anodized aluminum sheets are often utilized in the construction, automotive, aerospace, and electronics industries.

Anodizing makes the surface of aluminum tougher and less likely to scratch or corrode by adding a protective oxide layer. Anodized aluminum sheets are great for high-performance uses, especially in places where materials need to be able to handle harsh weather or chemicals.

Why Stainless Steel Is a Popular Material for Building and Making Things

There are several compelling reasons why stainless steel is one of the most common materials in the world. Because it is strong, long-lasting, and looks good, it is a great choice for many different fields, such as architecture, cars, food processing, and medicine. There are many grades of stainless steel, and each one is good for a certain job. Stainless steel lasts a long time and is dependable, from the kitchen sink to skyscrapers.

Stainless steel doesn’t rust, discolor, or corrode like other metals do. This is especially critical in building and manufacturing, where materials can be damaged by moisture and other corrosive substances. Stainless steel is also easy to care for, which makes it a good choice for long-term use.

Anodized aluminum sheets have a lot of good points.

People recognize that anodized aluminum sheets have a number of advantages, which include:

- Better Durability: The anodizing system makes the surface of the aluminum more difficult, which makes it less probably to wear out.

- Corrosion Resistance: Anodized aluminum does not rust, so it is excellent for use in out of doors and industrial settings.

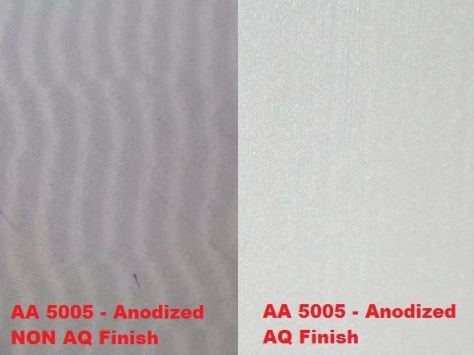

- The anodized coating offers matters a swish, metallic look that can be modified to different colors, which makes them look higher.

- Eco-Friendly: The electrolytes used in the anodizing procedure are safe for the environment; as a result, that is a long-lasting way to improve the qualities of aluminum.

Stainless Steel Suppliers: Meeting the Needs of the Industry

Stainless steel suppliers are very important since they give different industries the materials they need. They have numerous kinds of stainless steel, each with its own properties and functions. 304, 316, and 430 stainless steel are some of the most common varieties. They are all known for being resistant to rust and being useful in a wide range of situations.

Uses for Stainless Steel

- There are several uses for stainless steel, such as:

- Architecture: Used in decorative features, facades, and structural aspects.

- Automotive: For body panels, fuel tanks, and exhaust systems.

- Medical: For tools used in surgery, implants, and tools used to clean things.

- Food Processing: Stainless steel is a popular material in the food business since it doesn’t react with food and is easy to clean.

How to Decide Between Anodized Aluminum and Stainless Steel for Your Project

It depends on what your project demands, whether you should use anodized aluminum or stainless steel. Anodized aluminum is lighter and doesn’t rust easily, so it’s a great choice for projects where weight is important. Stainless steel, on the other hand, is stronger and lasts longer, so it’s better for projects that need more strength and resistance to mechanical stress.

For instance, anodized aluminum may be the satisfactory preference for the outside of a structure since it looks fine and is mild. Stainless steel, on the other hand, may be a preferable choice in case you’re making gadget as a gadget to be utilized in harsh conditions or with huge loads.

Conclusion

Anodized aluminum sheets and chrome steel are both true for distinct companies because they each have their own set of features. Anodized aluminum is popular because it appears suitable, will not rust, and is light. Stainless steel, on the other hand, is known for being sturdy, long-lasting, and useful in many situations. You can pick the material that works best for your project based on what you need. Dinco.ae and other vendors offer a variety of high-quality anodized aluminum and stainless-steel items that can be used for different purposes.

FAQs

- What is the difference between anodized aluminium and regular aluminium?

Anodized aluminium has a thicker oxide layer that enhances its durability and corrosion resistance, unlike regular aluminium which can be prone to scratching and corrosion.

2. Can anodized aluminium be painted?

Yes, anodized aluminium can be painted, but the paint will adhere better if the surface is prepared properly.

3. Is stainless steel resistant to rust?

Yes, stainless steel is highly resistant to rust and corrosion, making it ideal for use in harsh environments.

4. How do I choose the right grade of stainless steel?

The right grade depends on the application. For example, 304 stainless steel is commonly used in food processing, while 316 is used for environments with exposure to saltwater or chemicals.

5. Can anodized aluminium be used outdoors?

Yes, anodized aluminium is perfect for outdoor use due to its enhanced corrosion resistance and ability to withstand harsh weather conditions.